What Influences CNC Milling Machine Prices?

CNC milling machine prices can vary significantly depending on several important factors. Understanding what contributes to the cost allows buyers to determine which machine aligns with their budget and operational needs. One of the primary factors is machine size and configuration. Larger machines with higher axis counts typically cost more due to their expanded capabilities and structural requirements. Additionally, the type of materials used in the machine’s construction—such as cast iron for stability—can influence the price.

Another key element affecting pricing is the level of automation and control systems. Machines equipped with advanced computer numerical control (CNC) interfaces and software integrations generally come at a premium. These features can improve efficiency and reduce the learning curve for operators. Moreover, the brand reputation and after-sales support offered by manufacturers also add to the overall cost, as do geographic location and shipping fees. Buyers should also factor in the cost of installation, training, and ongoing maintenance.

Machine Types and Their Cost Implications

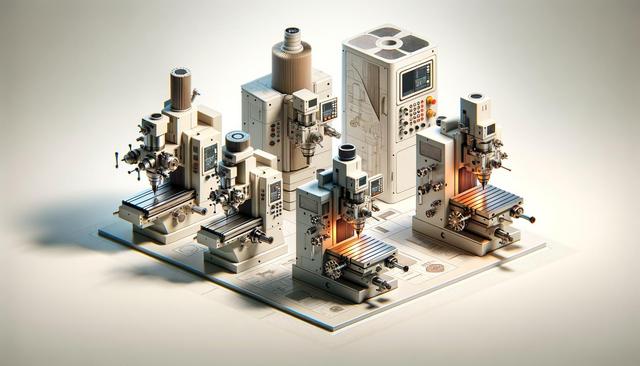

There are different types of CNC milling machines, each with its own price range based on capabilities and intended use. The most common types include:

- Vertical milling machines

- Horizontal milling machines

- 5-axis milling machines

- Mini CNC mills

Vertical CNC mills are typically more affordable and suitable for small to medium-sized parts, making them popular among small businesses and hobbyists. Horizontal mills, on the other hand, are often used in industrial applications and can be more expensive due to their higher material removal rates and rigidity. The 5-axis machines are among the most versatile and can handle complex geometries, but they require a larger investment. Mini mills, while limited in capability, are cost-effective options for prototyping or light-duty work.

The intended application also plays a role in the final cost. Machines designed for high-precision or high-speed applications often require specialized components, which can significantly increase the price. Buyers should consider not just the upfront cost, but also the long-term return on investment based on the machine’s performance and durability.

New vs. Used CNC Machines: Cost Considerations

When evaluating CNC milling machine prices, one important decision is whether to buy new or used. New machines offer the benefit of the latest technology, warranties, and manufacturer support. However, they typically come with higher price tags. Used machines can be significantly more affordable, but they carry certain risks, such as wear and tear, outdated components, and limited support.

To make a smart choice, consider the following:

- Check the machine’s maintenance records

- Inspect for signs of excessive wear

- Ensure compatibility with current software

- Consider the availability of replacement parts

Some reputable dealers refurbish used machines and offer limited warranties, making them a viable alternative for budget-conscious buyers. Additionally, leasing and financing options for new machines can make them more accessible without the need for full upfront payment.

Additional Costs Beyond the Machine

Beyond the initial purchase price, there are several other costs associated with owning and operating a CNC milling machine. These include tooling, software licenses, training, facility upgrades, and maintenance. Tooling costs can quickly add up, especially when working with different materials or complex part geometries. It’s essential to budget for appropriate cutting tools, vises, clamps, and other accessories.

Software is another consideration. While some machines include basic control software, advanced CAD/CAM packages often require additional investment. Training for operators and programmers is also crucial to maximize productivity and reduce errors. Depending on the machine’s requirements, some facilities may need upgrades such as reinforced flooring, proper ventilation, or three-phase electrical supply.

Ongoing maintenance and occasional repairs are inevitable. Establishing a preventive maintenance plan and working with a trusted service provider can help avoid unexpected downtime and costly breakdowns. Buyers should factor all these costs into their total cost of ownership calculations.

Finding the Right Supplier and Making an Informed Choice

Choosing the right supplier is as important as selecting the machine itself. Look for vendors who offer detailed product information, transparent pricing, customer reviews, and strong after-sales support. Some suppliers also provide training programs, installation services, and maintenance packages, which can add value to your purchase and improve operational success.

Before committing to a purchase, consider the following steps:

- Request demonstrations or virtual tours

- Compare quotes from multiple suppliers

- Ask about machine customization options

- Check for community forums or user groups

In addition, consider visiting trade shows or machinery expos to get hands-on experience with different CNC milling machines and speak directly with industry experts. Taking the time to research and consult with professionals can help you avoid costly mistakes and ensure the machine you choose fits your unique production goals and budget constraints.

Conclusion: Making Cost-Effective CNC Milling Decisions

Exploring CNC milling machine prices and options requires a careful balance of cost, capability, and long-term value. Whether you’re a small business looking to expand your machining capabilities or an established manufacturer upgrading your production line, understanding the various price factors and machine types can lead to a more informed and cost-effective decision. Always consider total ownership costs, supplier reliability, and future scalability when investing in CNC technology.